Complete range

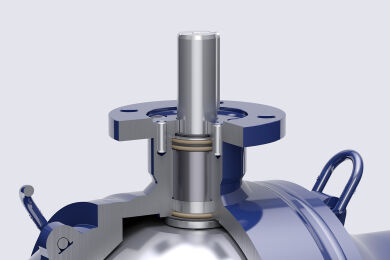

Valves are designed for above ground and underground installations to operate reliably even in the most demanding conditions. The range includes full bore and reduced bore valves in DN sizes 150–1200 with welded or flanged ends up to pressure class PN40.